Custom system Design

At Zaria Water, we are proud to offer custom water system designs to meet the specific needs of our clients. Our team of experienced engineers and designers work closely with clients to create bespoke systems that are tailored to their unique requirements. We specialize in providing custom designs for a wide range of applications, including estates, commercial properties, and industrial facilities. We understand that every client has different needs and priorities, and we take a collaborative approach to ensure that we create a system that meets their exact specifications. From the initial design concept to the final installation and commissioning of the system, we are committed to providing our clients with the highest level of service and quality.

Beyond Bottled Water

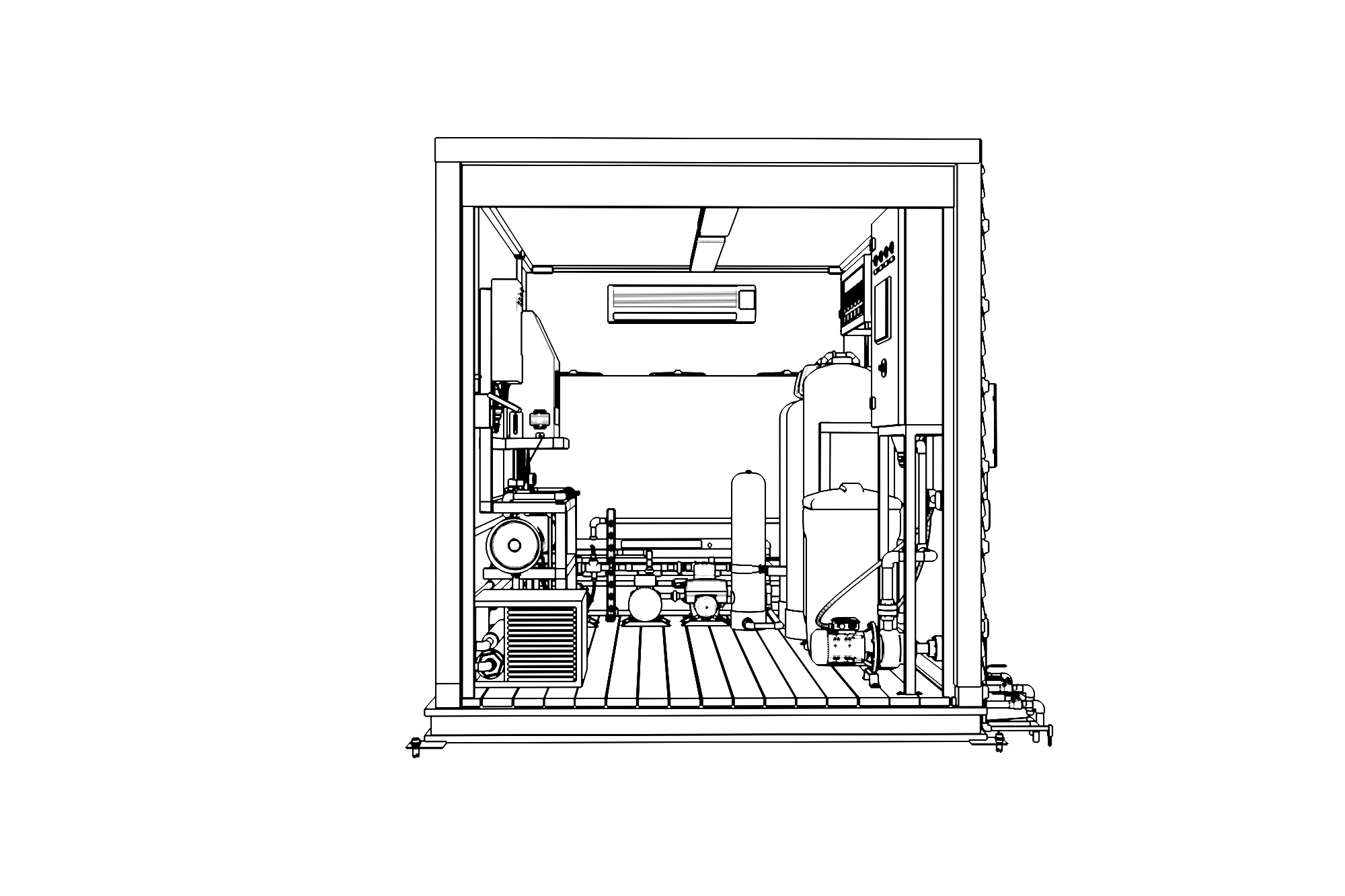

Front view

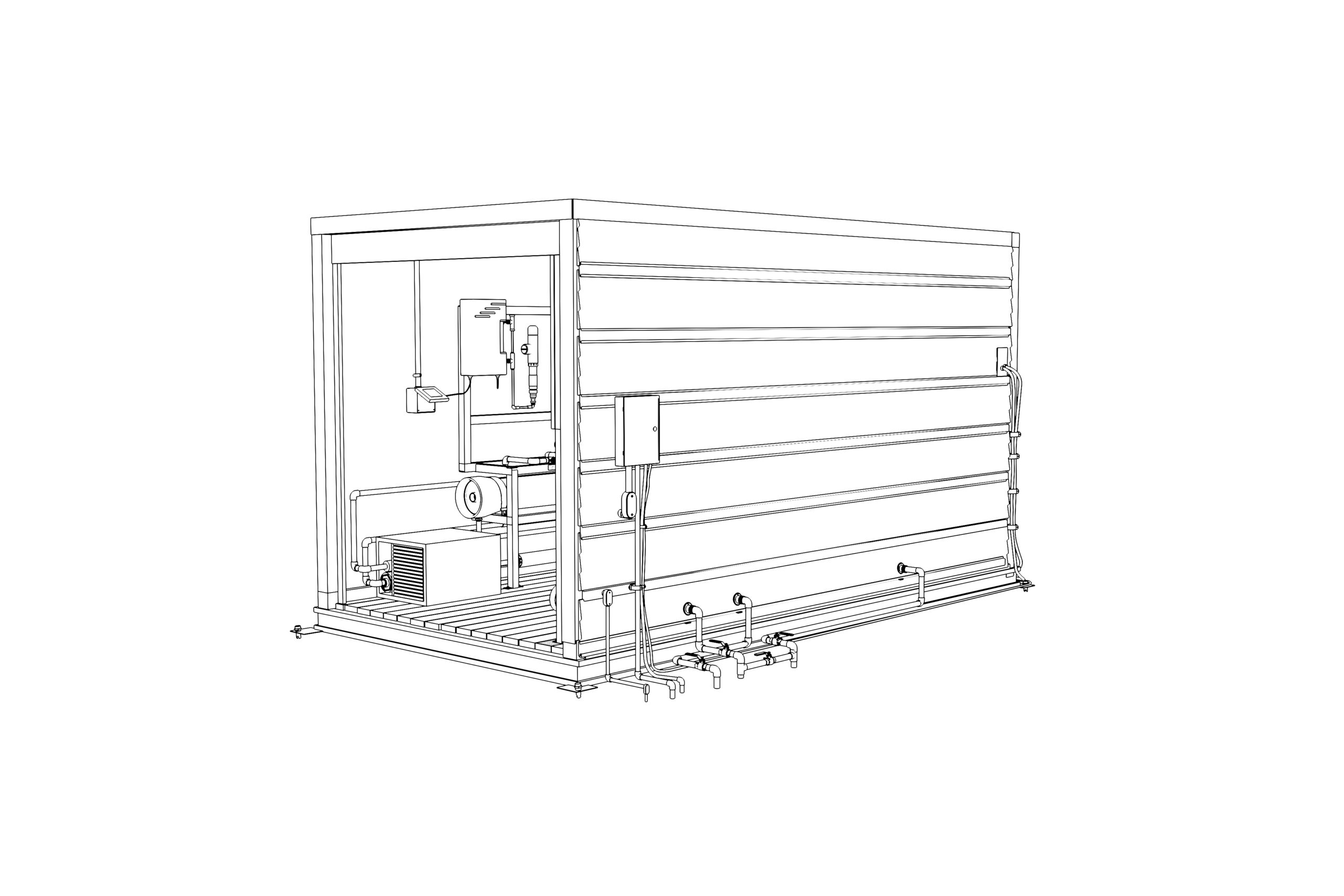

Perspective view

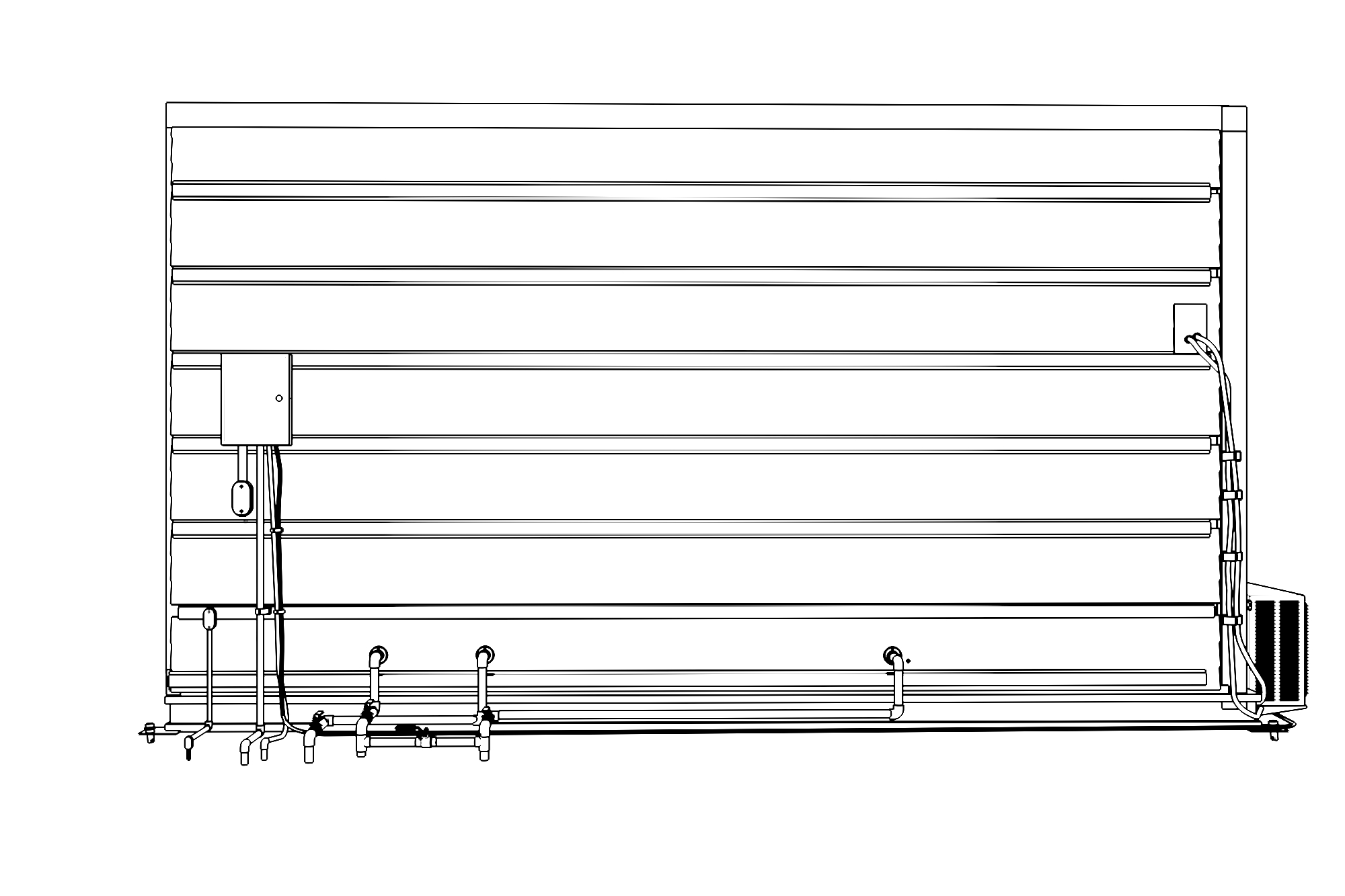

Right view

Back view

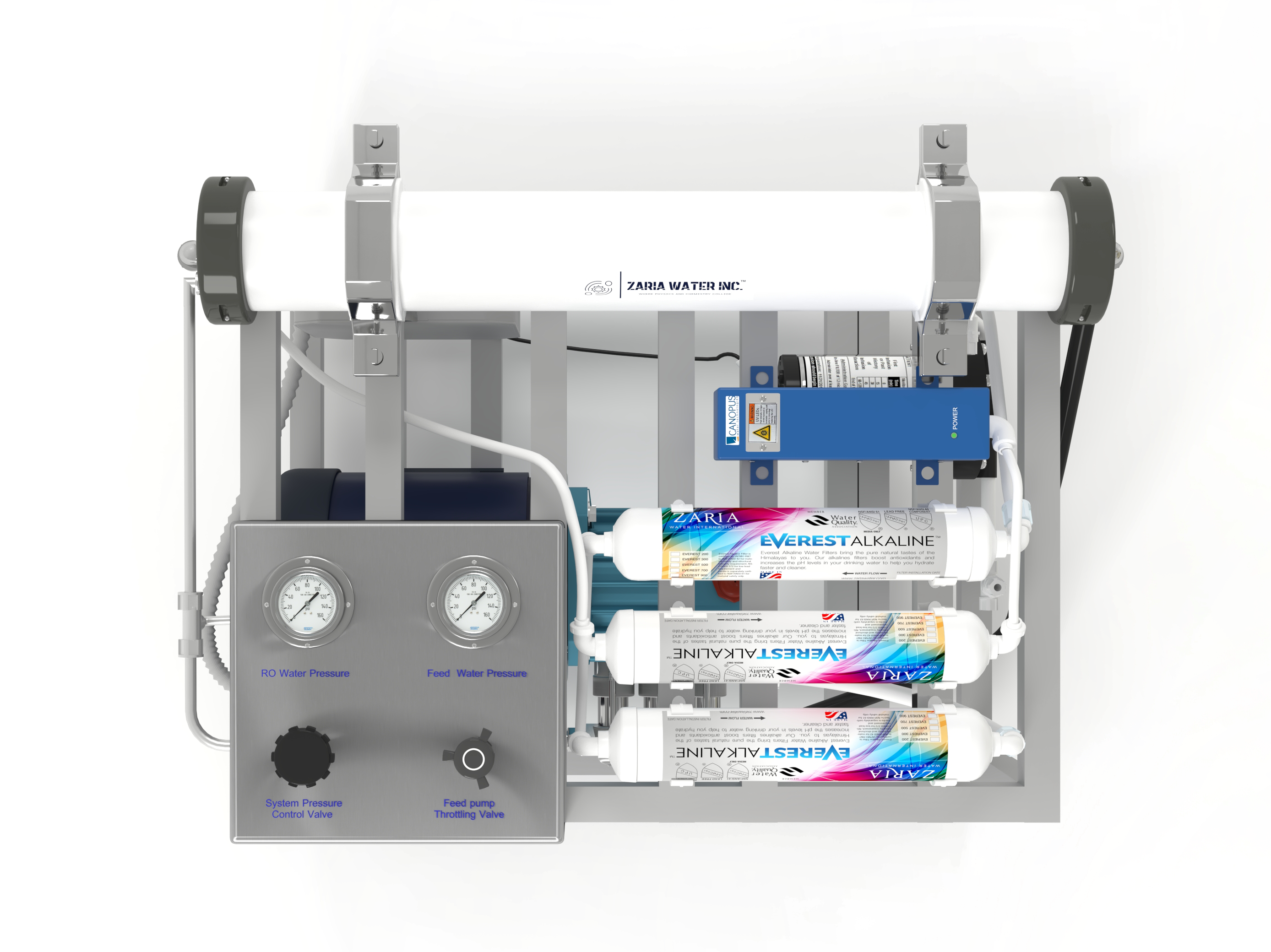

Emergency Drinking Water System

Our Expertise:

- Innovative Solutions: We have a track record of developing innovative filtration solutions for a wide range of industries and applications.

- Advanced Technology: Our team stays abreast of the latest advancements in filtration technology to ensure that our designs are cutting-edge and efficient.

- Client Collaboration: We believe in collaborating closely with our clients throughout the design process to ensure that their needs are met and exceeded.

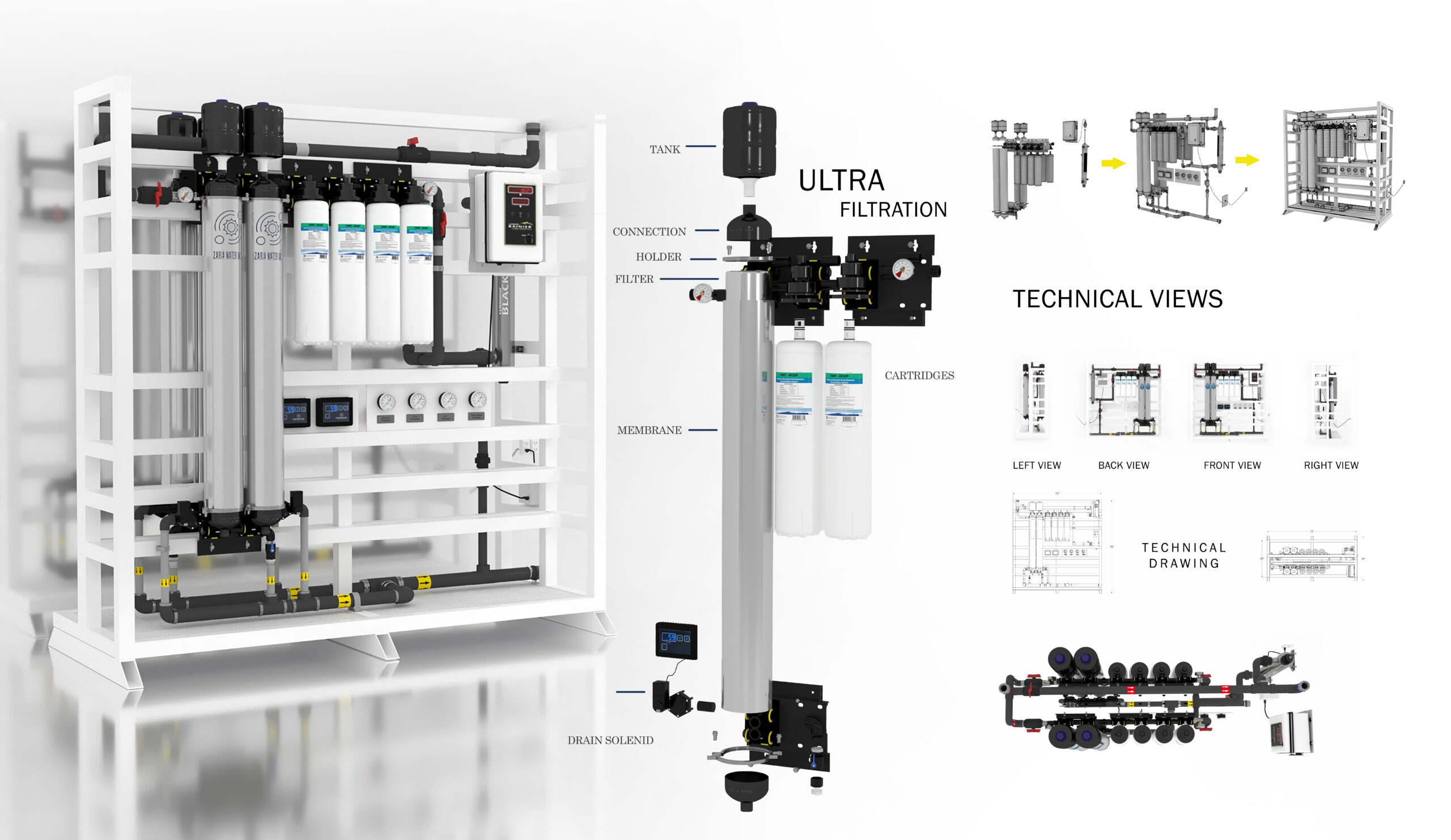

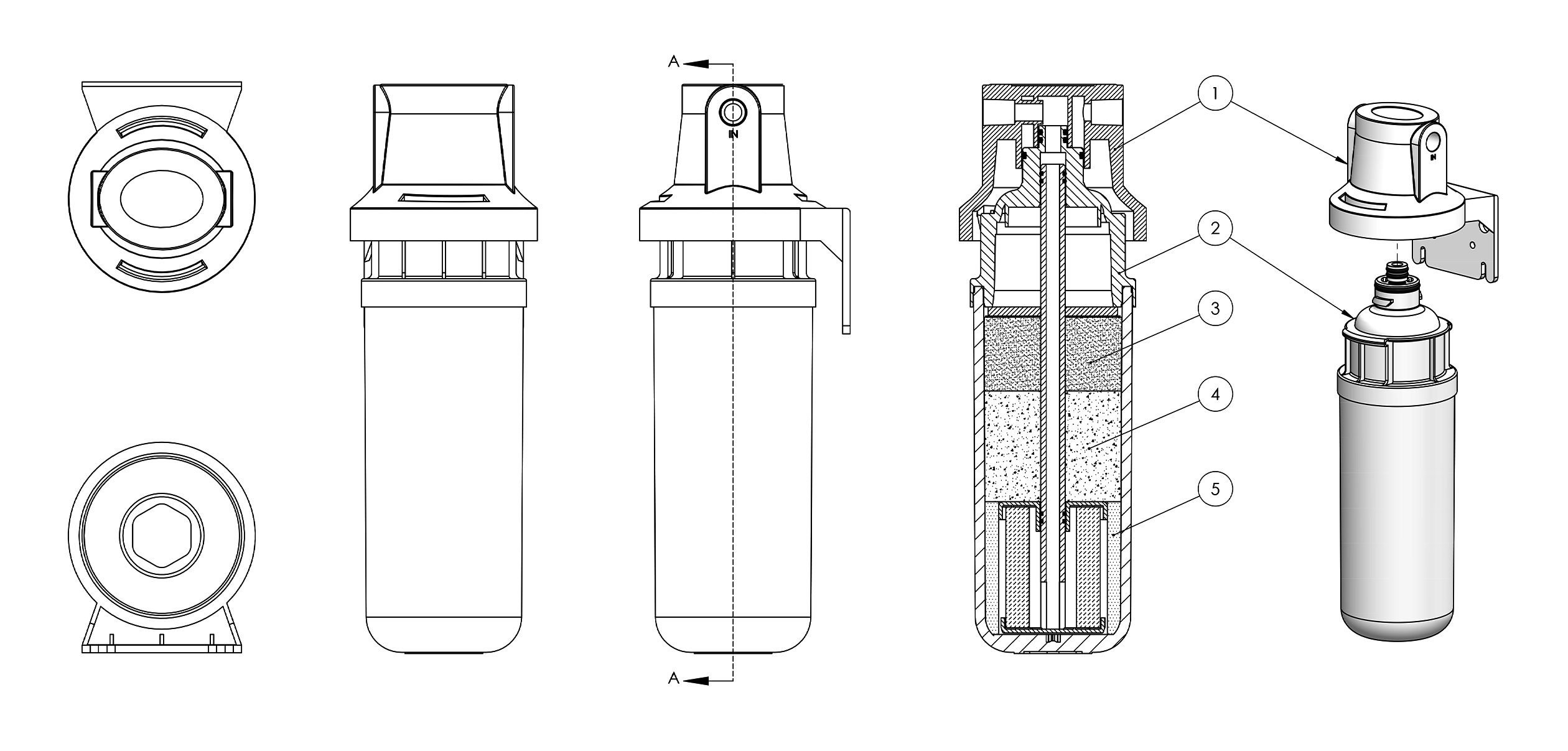

Custom Filter design

Design Concept

Our process begins with your vision. We collaborate with you to understand your specific filtration needs, considering factors such as application, environment, flow rate, and filtration efficiency. Our design team utilizes the latest CAD technology to create a detailed blueprint of your custom filter.

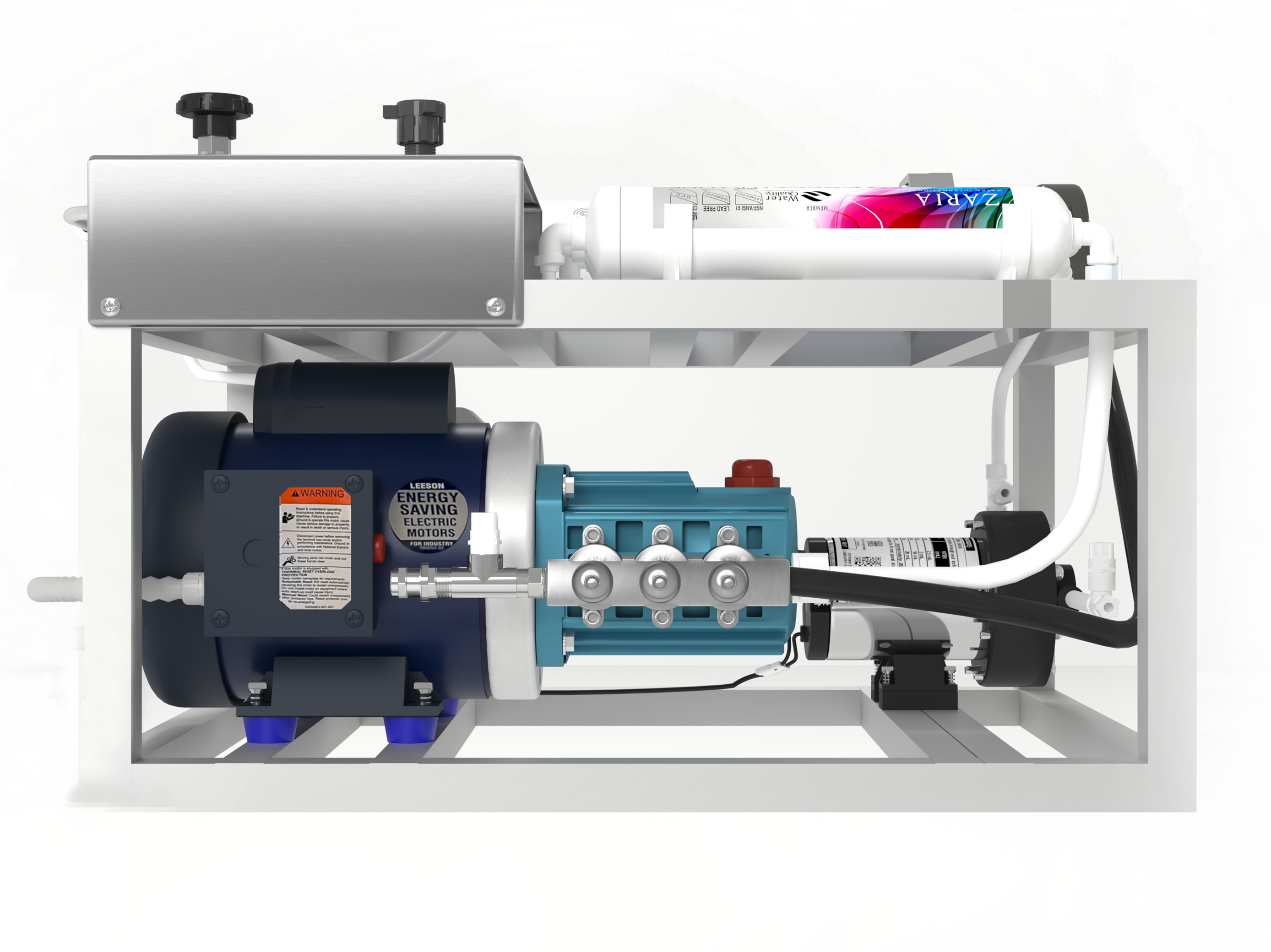

Technical configuration

We consider various factors such as water source quality, desired water output quality, flow rate requirements, and specific contaminants that need to be addressed. our engineering team designs a water filtration system that addresses your specific challenges. This includes selecting the appropriate filtration technologies, such as activated carbon filters, reverse osmosis membranes, UV sterilization, or sediment filters, and configuring them to work seamlessly together.

3D Design

With a design in hand, we move to production. Our manufacturing capabilities allow us to handle orders of any size with precision and efficiency. Throughout the process, we implement strict quality control measures to ensure each filter meets our high standards.

Prototyping and Testing

Before production, we develop a prototype of your filter to ensure it meets your requirements. Rigorous testing under real-world conditions allows us to refine the design as necessary, guaranteeing the final product performs as expected.

Production

Our Process:

-

Initial Consultation: We start by conducting a thorough consultation to gain a deep understanding of your filtration needs, challenges, and goals.

-

Design Concept: Based on our consultation, we create a design concept that outlines the proposed filtration solution, including specifications, materials, and expected performance.

-

Prototyping: Once the design concept is approved, we proceed to the prototyping phase, where we create a working prototype of the custom filter for testing and validation.

-

Testing and Optimization: We rigorously test the prototype to ensure that it meets the required performance standards. Any necessary adjustments are made to optimize the design for maximum efficiency.

-

Final Design: Upon successful testing and optimization, we finalize the design and prepare it for production.